From Molten Sand to Masterpiece: Inside the Science of Perfect Glass Clarity

Understanding Glass Clarity: Why It Matters for B2B Buyers

The Importance of Crystal-Clear Glass in Wholesale Orders

For B2B clients, the clarity of glass is more than just an aesthetic choice—it reflects the quality and professionalism of the brand. Restaurants, hotels, and premium retailers rely on crystal-clear glassware to present their products and services at the highest standard. Whether it is a dining table setting or a display shelf, clear glass enhances the overall customer experience and adds a touch of sophistication to the venue.

How Glass Clarity Impacts Brand Reputation

Transparency, absence of bubbles, and impurity-free glass are essential indicators of craftsmanship and reliability. High-quality glassware communicates attention to detail and strengthens the reputation of any business, making it an important factor for repeat orders and long-term partnerships.

The Science Behind Perfect Glass Clarity

Premium Raw Materials Selection

The journey to perfect clarity begins with the raw materials. High-purity silica and carefully chosen metal oxides form the foundation for crystal-clear glass. Consistency in raw material quality ensures even color, smooth surfaces, and the brilliance that distinguishes premium glassware.

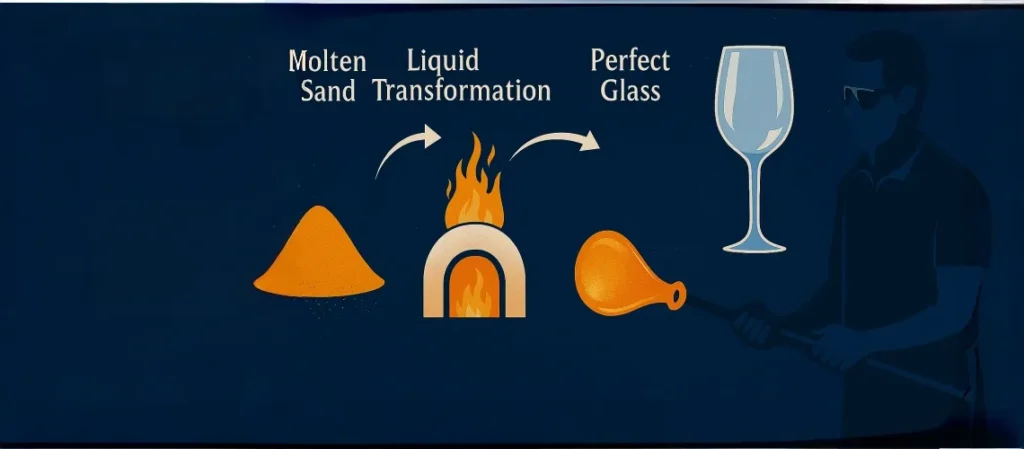

Melting and Refining Techniques

The melting process is critical in achieving flawless glass. Controlled furnace temperatures and precise refining techniques eliminate bubbles and impurities, producing a smooth, transparent surface. Attention to every stage of melting guarantees that the glass meets both aesthetic and functional requirements for high-end clients.

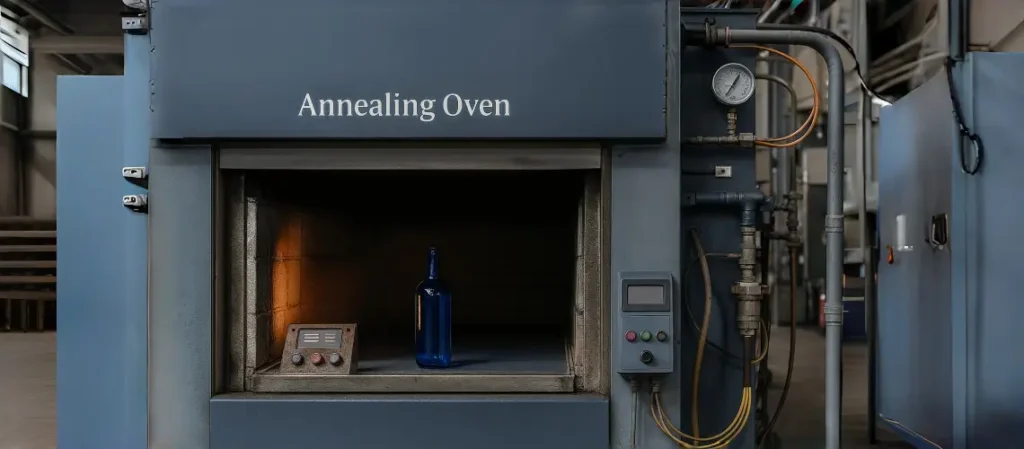

Annealing and Stress-Relief Processes

Once formed, the glass undergoes annealing to relieve internal stress. This process enhances strength, reduces the risk of cracks or breakage, and ensures the glass maintains its clarity and shine over time. Proper thermal control is essential to producing durable glass suitable for bulk orders and frequent use in commercial settings.

Innovative Techniques in Modern Glass Manufacturing

Combining Handcrafted Techniques with Automation

Modern glassmaking balances tradition with technology. Skilled artisans work alongside automated systems to create pieces that are both unique and consistently high in quality. This approach allows for large-scale production without sacrificing the artistry that distinguishes handcrafted glassware.

Quality Control Measures for Bulk Orders

Every batch undergoes rigorous quality control. Each piece is inspected for clarity, uniformity, and the absence of imperfections. By maintaining strict standards, suppliers can ensure that every wholesale order meets the expectations of discerning clients in hospitality and retail sectors.

Choosing the Right Glass Supplier for Perfect Clarity

Certifications and Material Transparency

Selecting a qualified supplier is crucial for B2B buyers. Suppliers with proper certifications and transparency in sourcing provide assurance of safe, high-quality glass that can withstand commercial use. This reliability is vital for hotels, restaurants, and bulk buyers who depend on consistent quality.

Customization Options for B2B Clients

Many suppliers offer customization services, allowing businesses to add logos, select specific sizes, or create unique patterns. Customized crystal-clear glassware can enhance brand identity, create memorable customer experiences, and differentiate a business in competitive markets.

Conclusion: From Molten Sand to Masterpiece

Perfect glass clarity is the result of careful material selection, precise manufacturing, and rigorous quality control. For B2B clients, partnering with a skilled and reliable glass supplier ensures consistent, high-quality products that elevate brand image and meet the demands of premium markets. From molten sand to a finished masterpiece, every step contributes to glassware that embodies both beauty and performance.